Planetary Roller Screw Products & Solutions

What are Planetary Roller Screws?

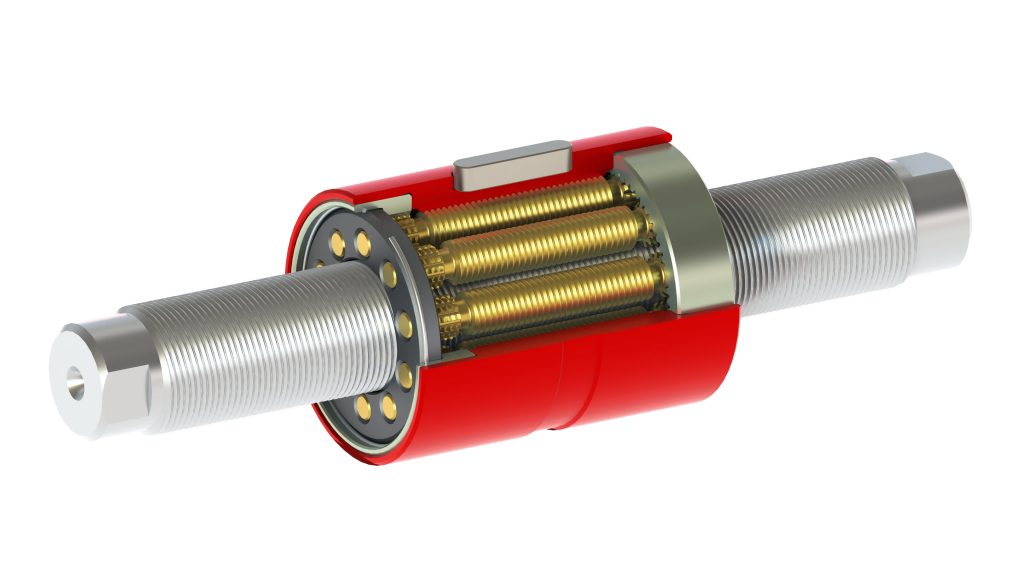

Planetary roller screws (or satellite roller screws) are a type of screw that transfers rotational forces to a linear movement. They are an integral part of operations in the industrial, aerospace, robotics, semiconductor, and scientific industries. They can handle extremely high load ratings and speeds at high efficiency, high positioning accuracy and with minimal friction.

Our planetary roller screws have a very high life span and require only minimal maintenance. This makes them an excellent choice when converting fluid power systems into servo motor driven electro-mechanical actuation. Our screws are divided into 4 main product groups:

Our primary screw type, the RV, is a workhorse suitable for many applications.

The HRV roller screw is a heavy-duty version of our RV planetary roller screw, used when longer service life or higher peak loads are needed.

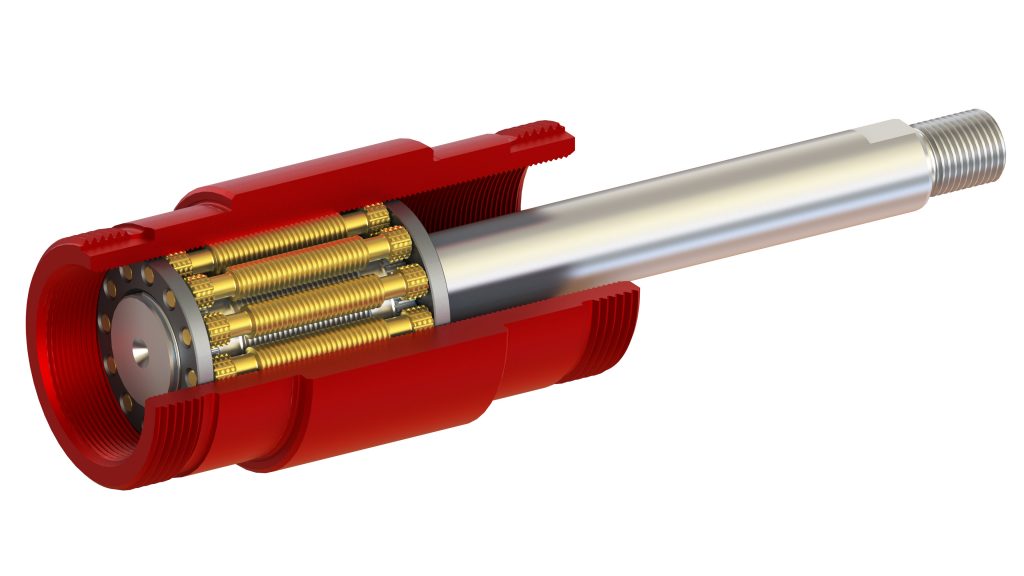

RVI screws make the most of small spaces. They are a popular choice for robotic arms in automotive spot welding applications.

Their unique design allows fully integrated and sealed constructions.

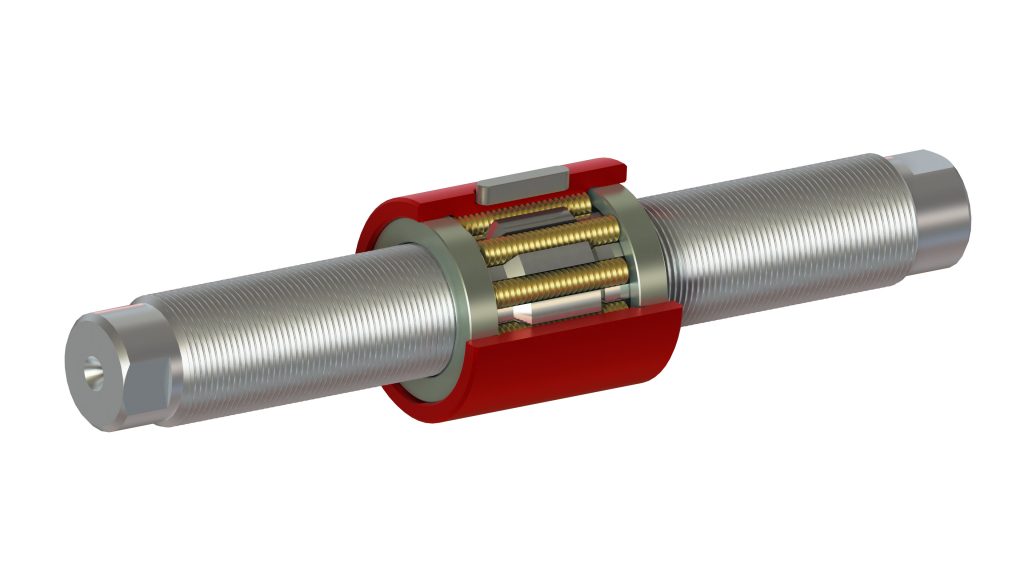

The RVR screw is a precision design that is often used in positioning systems in scientific applications or for precision grinding machines.

They are the best precision and stiffness combination.

Using our cutting edge technology, we are the only company able to produce RVD differential roller screws.

The RVD provides unrivaled precision for the most demanding applications, offering position on a nanometer scale.

Accessory Products

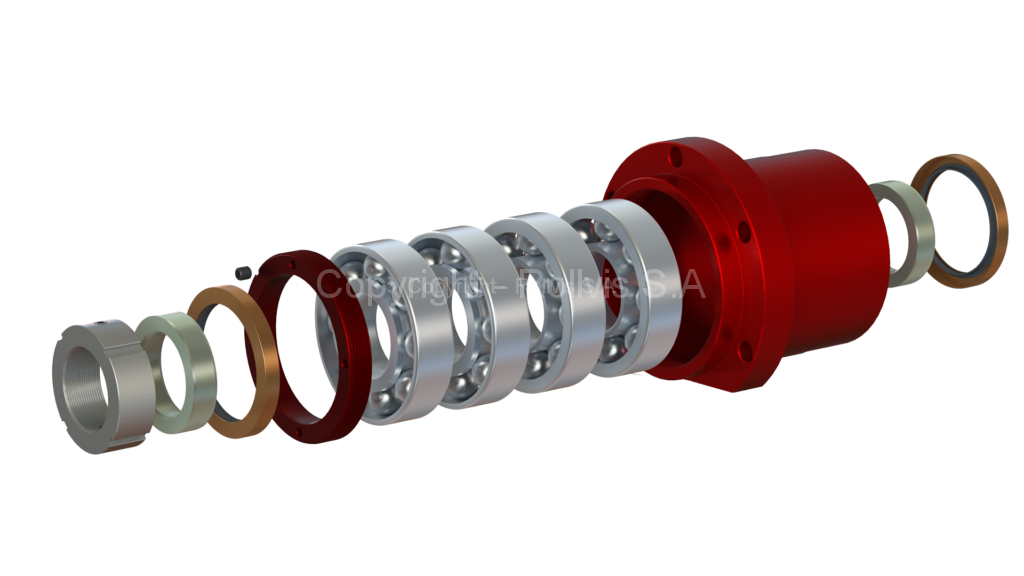

Each roller screw needs to have support bearings. As a service to our customers we offer a support bearing housing made for bearing bore diameters from 12 to 100mm. These units are populated with sets of 7300 series angular contact ball bearings which can be adjusted to meet the application demands.

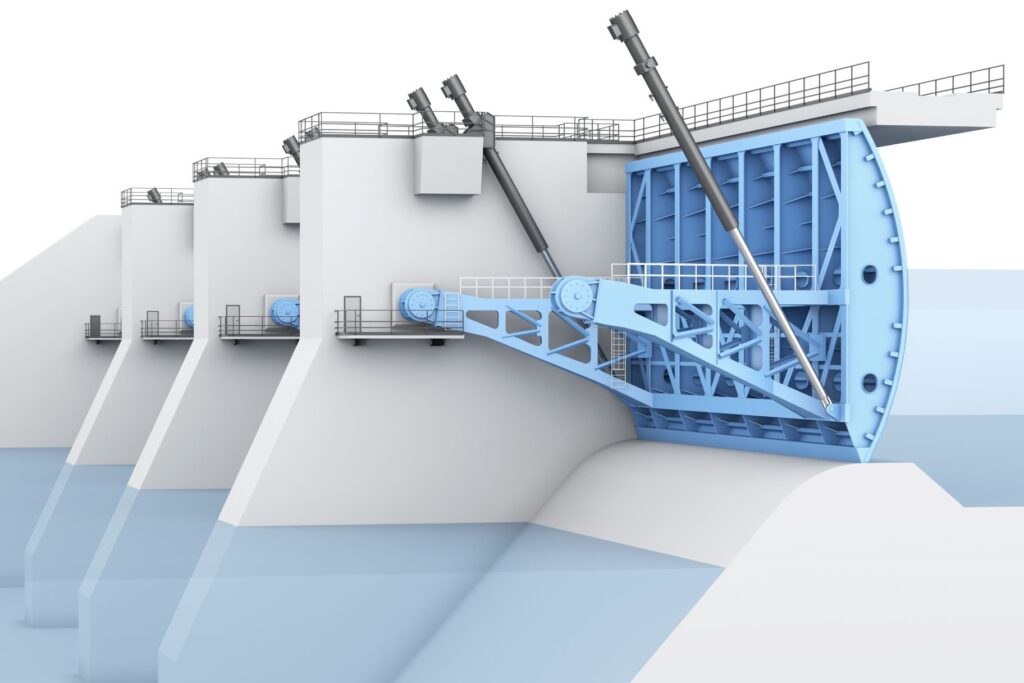

Applications for Roller Screws

Planetary roller screws are well-suited to applications that require high peak loads or high speeds. They are also a good choice for customers who seek a product requiring minimal maintenance.

At Rollvis SA, we have an unmatched focus on manufacturing and innovating satellite screws within the roller screw industry.

Our roller screws are commonly used in applications such as:

-

- Electric Actuators

- High-precision grinding and other machines

- Plastic injection molding equipment

- Robotic arms on spot welding systems in automotive manufacturing

- Robotics, exoskeleton and prosthetics that require precision within a very small size

- Oil & Gas equipment – Surface and Subsea, Tools & Equipment

- Scientific Research Equipment

- Aeronautic and Aerospace

Industries

Our satellite roller screws are in use in the aerospace, automotive, manufacturing, robotics, scientific, and semiconductor industries, where they can withstand high loads and speeds with little maintenance.

Our team manufactures roller screws from various steel alloys. We can also use specialty metals suitable for a wide range of applications, from lightweight prosthetics to stainless materials suited for use in outer space.