RVi Inverted Planetary Roller Screws

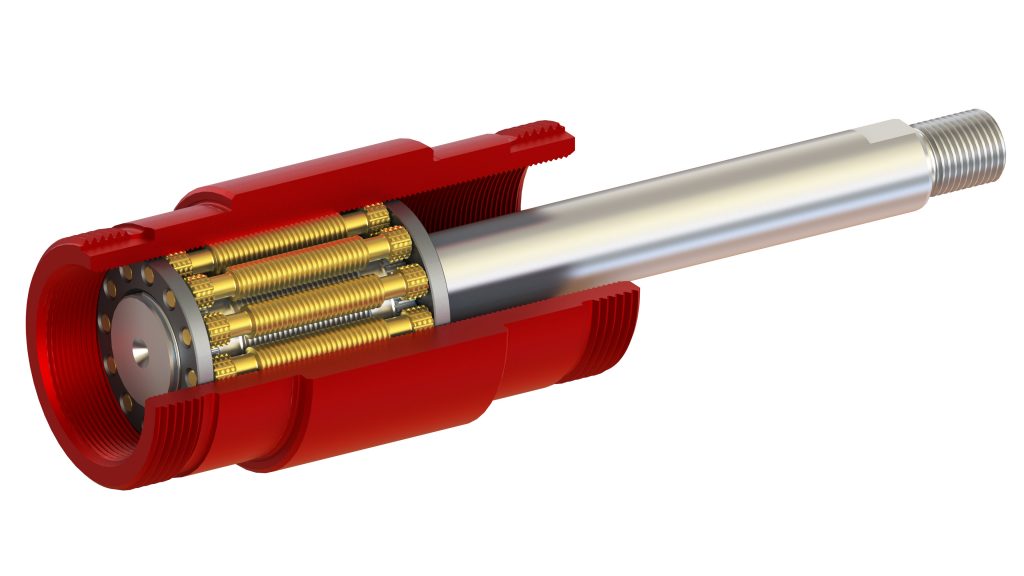

RVI inverted planetary roller screws combine precise linear operation with compact sizing, small lead measurements, and low weight. Inverted roller screws provide axial movement inside a threaded tube, with the small roller array remaining inside and a smooth screw shaft extending from the tube.

Discover the advantages of Rollvis RVI-series, inverted planetary roller screws, for complex applications. The custom design options available on the inverted design makes is possible for the screw to become part of the machinery making it possible to have less components in an assembly.

FEATURES

- Shaft diameters from 8 mm to 100 mm

- Leads from 1 to 16 mm

- The rollers move along the inside of the nut

- Smooth output shaft

- Thread sizes are larger for the same shaft/Nut diameter

- The nut is highly customizable

- Timing rings are built into the screw shaft.

BENEFITS

- Compact and Customizable:

- Low weight: Our specialized RVI rollers keep overall weight low, enhancing performance for robotic arm assemblies.

- Less complexity: With the screw or nut able to act as a push tube, the actuator system can have fewer parts, especially compared to hydraulic options.

- Smooth output shaft for exceptional sealing capabilities

- Lighter assembly weight

- Lower energy usage with increased step efficiency

- High Load Rating: due to the large number of contacts points sharing the load capacity

- Long service life for reduced downtime

- Speed and Acceleration: The design allows for best-in-class speed and acceleration limits.

- High rotational speed: Inverted roller screws move quickly and precisely

APPLICATIONS AND INDUSTRIES

These characteristics are ideal for tight tolerances and reduced spaces.

Our standard roller screws are an excellent fit for high-load automated manufacturing operations, but some applications require the improved sealing capabilities and lighter weight of RVI inverted roller screws:

- High Volume Automotive assembly processes such as Spot welding and riveting operations

- Robotic Joints such as knees and shoulders

- Compact Electro-Mechanical Actuators

When manufacturing applications require precision tools, high production volumes, heavy loads, and extended lifetime performance, the closed design of RVI inverted roller screws provides optimal results.

Innovative Automation Solutions for Manufacturers

Choose a world leader in automation and CNC system components. At Rollvis, we have over 50 years of experience designing high-performance machine components. Our team combines technical expertise, precision engineering, and next-generation materials to create customized linear motion components.

Contact us to discuss a complete list of industries and applications for RVi inverted roller screws.